Steel manufacturers demand immediate action as production falls by 30%.

The Pakistan Association of Large Steel Producers (PALSP) is sounding the alarm and asking the State Bank of Pakistan (SBP) to open letters of credit (LCs) and fix the severe shortage of rebars on the domestic market.

The situation has deteriorated to the point where imports for the first seven months of fiscal year 2013 were down 40% from the same period last year, when 2.5 million t were imported.

In January 2023, only 220,000 metric tonnes of refuse will be imported, the smallest January import in the last five years and a 50 percent decrease from January 2020.

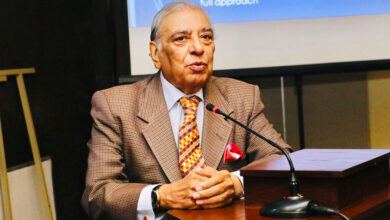

The secretary general of PALSP, Wajid Bukhari, said that this is the worst crisis in the steel industry since records began.

“In the coming months, the factories will have to close because they can’t get the raw materials they need,” he said.

The shipbreaking industry, which uses 15% of all local raw material scrap, is only running at 5% capacity. This means that the entire long steel industry can only run at 30% capacity, and the situation is expected to get worse in the coming months.

“The lack of rebar on the domestic market is a significant concern for the steel industry and its consumers. Bukhari stressed that the SBP must act immediately to open Letters of Credit in order to address the severe shortage of raw materials and guarantee the smooth operation of the steel industry.

“The imports of raw materials have more than halved compared to the previous fiscal year, which is alarming and contributes to the market shortage of rebars. The situation will only worsen if the SBP does not act immediately.”

In addition to causing problems for the steel industry, the shortage also negatively affects its customers. Even though rising prices continue to irritate the construction industry, real builders who have received billions of rupees from investors and potential tenants are still building their projects.

Approximately 80% of the reputable builders are continuing their projects and honouring their commitments, according to PALSP, because they secured raw materials in advance from the rebar manufacturers with the funds received during the launch of their projects.

However, the actual issue will arise when rebar manufacturers cease production in the future due to a lack of supply.

Due to the shortage, additional price increases cannot be ruled out in the coming weeks. The price of domestic refuse has increased from Rs 120,000 per tonne to over Rs 200,000 per tonne, a 40 percent increase in a matter of weeks.

PALSP urges the Ministry of Industries to adopt a scrap recycling policy similar to India’s in order to increase domestic production and decrease prices.

Because of the sharp rise in local scrap prices and the inability to import raw materials, about 80% of small and medium-sized mills had already shut down, signalling a huge wave of joblessness.

Additionally, 45 allied industries are connected to the steel industry, and 7.5 million jobs will be at risk if the LCs are not opened immediately.

The PALSP urges the SBP to take immediate action to guarantee that the LCs are opened. Now is the time to act to prevent the situation from deteriorating further.