Pakistan to produce locally manufactured ventilators

Pakistan to produce locally manufactured ventilators

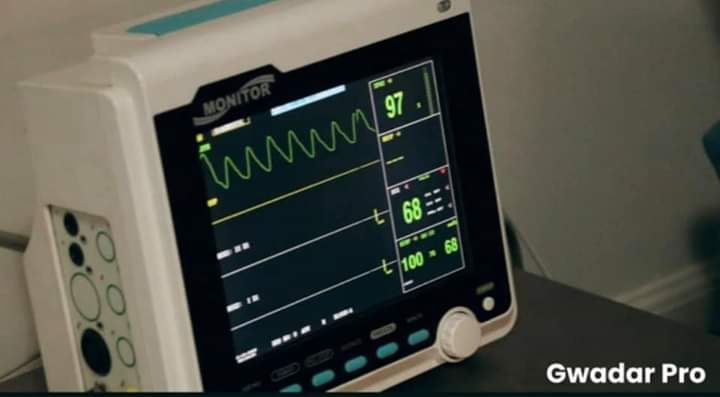

ISLAMABAD, May 1 (Gwadar Pro) -The spread of COVID-19 has resulted in a worldwide shortage of essential medical supplies, especially ventilators that help critical patients breathe when their lungs are not functioning properly. In Pakistan, the demand for the life-saving machines has surged after the number of novel coronavirus cases in the country witnessed exponential growth during the past few weeks.

Prime Minister Imran Khan therefore asked the industries to produce locally manufactured ventilators. While addressing a ceremony in Islamabad on Thursday, Prime Minister Imran Khan said that Covid-19 crisis has provided an opportunity for Pakistan to produce locally manufactured ventilators and personal protective equipment (PPEs) as everything cannot be imported. “Self-belief is the solution for development, progress, and self-reliance. We have to go towards a knowledge economy, education, science and technology to get a dignified place among the comity of nations” Prime Minister further added.

Since the first COVID-19 patient was confirmed in the end of February, the questions raised were whether the country had qualified medical workforce and equipment to tackle this challenge. There was a big question about the number of ventilators in the country and the fraction of those that were functional.

In a briefing to the parliamentary committee on COVID-19, Lt Gen Muhammad Afzal, the National Disaster Management Authority (NDMA) chairman said that there are more than 3,800 ventilators in the country of which 2,200 are owned by the public sector. He said around 500 more ventilators will reach the country from China during the same week and another 2,000 will arrive later.

Due to the shortage of ventilators in the country, many initiatives were taken to manufacture ventilators locally. In a meeting called by the Pakistan Engineering Council (PEC) in March, six research groups sought approval for their projects. These included two Pakistani inventors holding US patents. Their designs were chosen for clinical trials and production. Factories operating under the Ministry of Defense Production (MODP) would support mass production of the equipment. According to Dr. Sidiqqui since that meeting, the number of groups working on indigenous ventilator designs has increased to more than 50.

Moreover, an informal coalition calling itself Pakistan against Covid-19-Volunteers (PAC-V) which includes professionals from health, engineering and business sectors, is focusing on medical supplies required during the pandemic. The members of the group used 3D printing to produce splitters allow a ventilator to be used for up to four patients.

Dr. Athar Osama, a consultant and program chair of the Higher Education Commission‘s (HEC’s) Grand Challenge Fund said that there might be a need to manufacture essential medical equipment at home if the country wants to be better prepared for the challenge.

In a research paper, Osama suggests that automotive parts manufacturers and light engineering industry can be repurposed to manufacture ventilators.

During these testing times, many local companies have started to develop prototypes of ventilators which are economically feasible as well as easier to manufacture. Alpha Rubber and Plastic Works, a Lahore-based company which manufactures auto parts, has developed a splitter which connects to the ventilator hoses and supplies oxygen to two to four patients at once and may be used multiple times.

Osama Usman, head of the firm claimed that Punjab IT Board (PITB) has already approached them to manufacture the connector using 3-D printer prototype. This would result in higher production rate and wouldn’t require much labor. “Now we are manufacturing 1,000 ventilator connectors daily which is being supplied to various government and private hospitals in Punjab,” he said during an in interview.

Several prototypes of ventilators have been shared with the Pakistan Engineering Council (PEC) and the Drug Regulatory Authority of Pakistan (DRAP). Once these are approved the Pakistan Association of Automotive Parts and Accessories Manufacturers (PAAPAM) has offered to manufacture ventilators to meet the projected national demand.

Recently the Pakistan Engineering Council allowed testing of locally produced ventilators to begin. A document issued by the council read that a special team has been formed by the Ministry of National Health Services, Regulation and Coordination to evaluate the testing of these ventilators. The procedures have already begun and have been based on consensus by engineering experts.

According to the council, the testing procedures of these machines will be evaluated after every six months if required. “The whole process is being fast tracked to meet the emergency requirement of the COVID-19 pandemic,” the document added. Once ready, these ventilators will be installed in hospitals across the country.

Pakistan has a very limited number of ventilators and has been importing them for millions of rupees. These locally manufactured ventilators are expected to bring relief for the government and the health sector as they will be cheaper than the imported ones.