ASML, a big company that makes computer chips, bets a lot on a tiny future.

VELDHOVEN, Netherlands (Reuters) – ASML, a stock market and semiconductor industry giant, needs to think smaller. Or maybe bigger.

It is building machines the size of double-decker buses and weighing more than 200 tons in order to make beams of focused light that make the tiny circuitry on computer chips used in everything from phones and laptops to cars and artificial intelligence.

The company has had a great decade. Its stock has gone up by 1,000%, making it worth more than 200 billion euros, and it has gotten most of the lithography business in the world.

It is now getting ready to release a new $400 million machine for making next-generation chips, which it hopes will be its main product by the late 2020s but is still an engineering challenge for now.

Executives at the headquarters of ASML in the Dutch city of Veldhoven told Reuters that a prototype should be ready in the first half of 2023. They said that the company and its longtime research and development partner, IMEC, were setting up a test lab right there, which was a first, so that top chipmakers and their suppliers could learn about the machine’s properties and get ready to use production models as early as 2025.

Investors expect ASML to continue to be dominant and grow, which is why the company is valued at 35 times its earnings in 2021. This leaves little room for error if the company runs into technical or supply-chain problems.

Christophe Fouquet, who is in charge of EUV programs at ASML, said, “Right now, every check is green.” “But, you know, we still need to see everything put together.”

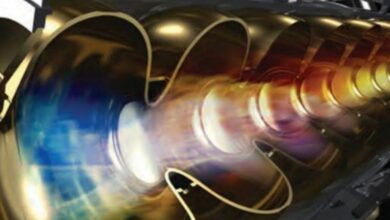

EUV stands for “extreme ultraviolet.” The most advanced machines made by ASML use this kind of light.

The success of the project is also important for ASML’s customers, who are racing to make more chips because there is a shortage around the world. There’s Intel (NASDAQ:INTC) from the U.S., Samsung (KS:005930) from South Korea, and TSMC, the biggest, from Taiwan. TSMC makes chips for Apple (NASDAQ:AAPL), AMD, and Nvidia (NASDAQ:NVDA).

Dan Hutcheson of VLSI Research, an expert in the industry who is not part of the ASML project, said that the new technology, which is a “High-NA” version of EUV, could give some chipmakers a big advantage.

He said, “It’s kind of like who has the best gun.”

“So either ASML makes it happen or they don’t,” he said. “But if they do it and you don’t have your orders, you’ll miss out on this and you’ll be out of business right away.”

He said that TSMC beat out its competitors because it integrated ASML’s EUV machines first in the late 2010s. Intel CEO Pat Gelsinger has promised not to make the same mistake with High-NA.

Lithography is a key factor in how small the circuitry can get on a chip, and High-NA promises a 66 percent reduction. The more transistors you can fit on a chip in the same amount of space, the faster and more energy-efficient it can be.

Now that circuitry is getting closer to the atomic level, it is thought that “Moore’s Law,” which says that the number of transistors on a microchip doubles about every two years, is coming to an end.

“If they (ASML) don’t succeed, Moore’s Law will be hard to keep up with,” said Jos Versteeg, an analyst at the Dutch bank InsingerGilissen. However, he pointed out that engineers have overcome similar doubts in the past.

FIRST LIGHT ON SILICON

Since 2000, ASML has quickly taken market share from Japanese competitors Nikon (OTC:NINOY) and Canon, which now mostly focus on older technology. ASML has more than 90% of the market for lithography. No competitor is trying to build an EUV system because it would cost too much to do so.

Chipmakers can’t make enough chips because they can’t get enough of ASML’s machines, which cost up to $160 million each. To meet demand, chipmakers plan to spend more than $100 billion over the next few years to build more fabrication plants.

The High-NA machines will be about 30 percent bigger than their predecessors, which require three Boeing (NYSE:BA) 747s to carry them in sections.

IMEC, a non-profit research group that works with companies in the semiconductor industry, thinks that setting up the lab at ASML could cut up to a year off the time it takes to make new products.

ASML said it had five orders for pilot machines that would be delivered in 2024 and “more than five” orders from five different customers for faster production models that would be delivered starting in 2025.

But this isn’t a sure thing.

Carl Zeiss in Germany is having a hard time putting together a lot of complicated parts, like an optics system made of polished, super-smooth curved mirrors that are being built in a vacuum.

Versteeg at InsingerGilissen said that even though ASML had almost a monopoly, its prices depended on how well its machines worked. In the meantime, it has to sell EUV tools to the few companies left that make cutting-edge chips, such as SK Hynix and Micron, which make memory chips (NASDAQ:MU).

ASML is also tied to the larger fortunes of the cyclical chip industry, whose annual sales are expected to double this decade, passing $1 trillion.

Fouquet is most worried about problems with the supply chain.

“Right now, like with every other product, we’re seeing some stress in the supply chain. If you ask me, this is probably the biggest problem we’re facing with High-NA right now.”